Marvel produces various marking methods, like rubber masks and grit etching machines, for window and glass door manufacturers that require general logo marking, thickness marking and SGCC certification.

Grit etching or abrasive blasting is the process of marking various materials, such as glass, concrete or wood, with a specific set of numbers or letters for identification purposes.

The process uses a pneumatic force, such as an air compressor, to push a high-pressure stream of grit into a stencil that is specially made for this purpose. This process removes any impurities on the surface and makes a clean, legible mark on the material.

Etching marking via abrasive blasting is the industry standard for permanent glass identification, allowing manufacturers to apply logos, safety certifications, and other vital identification codes with high precision. To achieve a crisp logo grit mark, the process involves:

You will need to use different types of blasting media depending on the type of material you are etching. Fine sand, glass beads and aluminum oxide are all possible materials.

For glass etching, it is best to use glass beads or aluminum oxide grit, and you typically want to select 120 particle grit or higher for more control and finer etching. Start at a low pressure to avoid going too deep into the material.

You should always take safety precautions during this process. Remember to wear safety glasses, full body protection and a rubber mask to protect yourself from inhaling any particles and prevent eye irritation.

The quality of a glass etch depends on the glass abrasive used. When selecting grit for glass applications, consider the following particle types:

Marvel Marking manufactures specialized glass etching machines designed for high-volume production and mobile field work. Our industrial etching machines for glass are categorized by application:

Marvel grit etching machines offer operator friendliness and excellent marking capabilities for repeatable, clear and precise results. Users can switch glass thicknesses and types with efficient change-out operations.

All of our machines use air grit etching, meaning they require an air compressor and 110v electrical hookup, except for the handheld Model 5152, which requires only compressed air. These machines are ideal as glass etching machines and work extremely well for marking sheets of flat glass. Information on our most popular grit etching machines is listed below:

The Model 603B "benchtop" grit etching machine is our most popular glass marking machine. This model is controlled using a foot switch, allowing for easy operation in a production environment.

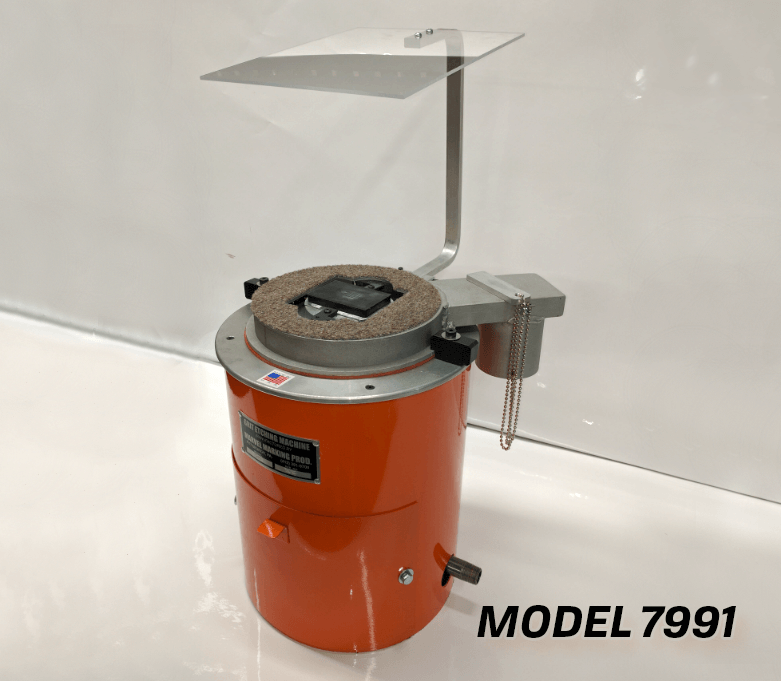

The 7991 is the same base model design as the 603B, and includes a vacuum system for dust collection, making for cleaner operation. Excess grit is collected in a holding can to be reused. This is also considered a "benchtop" model.

The Model AG-5152 grit-etching machine is designed for marking items in the field, or for shorter production runs. This handheld model requires the glass being marked to be oriented in a vertical position, whereas the 603B and 7991 are great for assembly line style production where the glass is laid horizontally, such as when it is coming off of an air table. The maximum marking area is approximately 2.5” wide x 1.4” tall. The Model AG-5152 is controlled using a hand trigger, and requires an air compressor for operation. The AG-5152 is an upgraded version of the formerly available Model 5152, now featuring a billet frame rather than the previous model's pot-aluminum casting, providing a more robust unit.

Model 603B-H is built on the foundation of the model 603B (pedal operated, running on 110V and compressed air), but with a remote marking gun attached via a 10-foot-long integrated airline and return tube. This machine was designed to mark glass that is vertical (or very nearly vertical, such as on a rack or vertical glass line), but it can also be used to mark horizontal glass on the top or bottom face.

The Model 7995 features a vacuum unit as well, and is what we consider to be a "floor model", as it has a larger footprint than the 603B/7991. These machines are popular with our high volume customers who etch larger layouts in their glass. This model is also controlled using a foot switch for operation. The maximum marking area is approximately 2.5 inches wide by 1.4 inches tall.